|

ADAM-4000 DAQ Series Used in Berlin's

Tunnel Construction Project

Introduction

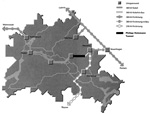

When

Berlin's electric utility proposed building a 9 km 9 km long 380-kV

overhead line from Berlin's northern city boundary at Spandau

to a transformer station in the city, it caused an uproar among

citizen's groups and policy makers. Be-cause of the resistance

it encountered, only 1 km of the line was built above ground.

The other 8 km was built in a tunnel under Berlin. This large-scale

project was completed by several builders - one of them being

Philipp Holzmann AG. The portion of the project built by Philipp

Holzmann AG was an underground section of the line approximately

3 km long. When

Berlin's electric utility proposed building a 9 km 9 km long 380-kV

overhead line from Berlin's northern city boundary at Spandau

to a transformer station in the city, it caused an uproar among

citizen's groups and policy makers. Be-cause of the resistance

it encountered, only 1 km of the line was built above ground.

The other 8 km was built in a tunnel under Berlin. This large-scale

project was completed by several builders - one of them being

Philipp Holzmann AG. The portion of the project built by Philipp

Holzmann AG was an underground section of the line approximately

3 km long.

System Requirements

Tunnel construction now follows a

fairly standard procedure: First, several propulsion presses drill

the tunnel under high pressure. Then mortar is pressed into the

soil under high pres-sure in order to stabilize it. During thethird

step, a concrete ring is constructed in the tunnel. Here the propulsion

presses are brought in again and the ring is built using individual

concrete segments. When the concrete ring is completed in one

section of the tunnel, the next drilling process begins. All process

data, such as the pressure of the propulsion presses, propulsion

rates, air consumption, mechanical handling capacities, and operating

hours are monitored, logged and archived.

System Description

Advantech

ADAM modules are used in this data acquisition and monitoring

process. The analog and digital signals from the sensors are fed

from the tunnel over an RS-485 bus system to the monitoring PC.

The length of this RS-485 bus can extend up to 2.5 km and repeaters

are necessary. Two ADAM-4017 analog input modules and two ADAM-4052

digital input modules are used for data acquisition, and two ADAM-4510

repeater modules spaced approximately one kilometer apart are

used to give the RS-485 signals the necessary range. The data

acquisition modules are located close behind the drill. The RS-485

bus is a simple twisted pair of wires, which is pulled tight behind

the propulsion press, together with the telephone line. The measured

values are registered, archived and logged using the process visualization

software WinLab/E, both during the drilling operation and in the

stop mode. WinLab/E is a product of the German software company

Graf Elektronik Systeme GmbH. The system uses 16 analog channels

(4- 20mA) and 14 digital channels for data registration. The system

is very flexible since the ADAM modules' upper and lower bounds,

alarm bounds and designations can be changed "on-line". Advantech

ADAM modules are used in this data acquisition and monitoring

process. The analog and digital signals from the sensors are fed

from the tunnel over an RS-485 bus system to the monitoring PC.

The length of this RS-485 bus can extend up to 2.5 km and repeaters

are necessary. Two ADAM-4017 analog input modules and two ADAM-4052

digital input modules are used for data acquisition, and two ADAM-4510

repeater modules spaced approximately one kilometer apart are

used to give the RS-485 signals the necessary range. The data

acquisition modules are located close behind the drill. The RS-485

bus is a simple twisted pair of wires, which is pulled tight behind

the propulsion press, together with the telephone line. The measured

values are registered, archived and logged using the process visualization

software WinLab/E, both during the drilling operation and in the

stop mode. WinLab/E is a product of the German software company

Graf Elektronik Systeme GmbH. The system uses 16 analog channels

(4- 20mA) and 14 digital channels for data registration. The system

is very flexible since the ADAM modules' upper and lower bounds,

alarm bounds and designations can be changed "on-line".

|

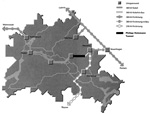

When

Berlin's electric utility proposed building a 9 km 9 km long 380-kV

overhead line from Berlin's northern city boundary at Spandau

to a transformer station in the city, it caused an uproar among

citizen's groups and policy makers. Be-cause of the resistance

it encountered, only 1 km of the line was built above ground.

The other 8 km was built in a tunnel under Berlin. This large-scale

project was completed by several builders - one of them being

Philipp Holzmann AG. The portion of the project built by Philipp

Holzmann AG was an underground section of the line approximately

3 km long.

When

Berlin's electric utility proposed building a 9 km 9 km long 380-kV

overhead line from Berlin's northern city boundary at Spandau

to a transformer station in the city, it caused an uproar among

citizen's groups and policy makers. Be-cause of the resistance

it encountered, only 1 km of the line was built above ground.

The other 8 km was built in a tunnel under Berlin. This large-scale

project was completed by several builders - one of them being

Philipp Holzmann AG. The portion of the project built by Philipp

Holzmann AG was an underground section of the line approximately

3 km long.  Advantech

ADAM modules are used in this data acquisition and monitoring

process. The analog and digital signals from the sensors are fed

from the tunnel over an RS-485 bus system to the monitoring PC.

The length of this RS-485 bus can extend up to 2.5 km and repeaters

are necessary. Two ADAM-4017 analog input modules and two ADAM-4052

digital input modules are used for data acquisition, and two ADAM-4510

repeater modules spaced approximately one kilometer apart are

used to give the RS-485 signals the necessary range. The data

acquisition modules are located close behind the drill. The RS-485

bus is a simple twisted pair of wires, which is pulled tight behind

the propulsion press, together with the telephone line. The measured

values are registered, archived and logged using the process visualization

software WinLab/E, both during the drilling operation and in the

stop mode. WinLab/E is a product of the German software company

Graf Elektronik Systeme GmbH. The system uses 16 analog channels

(4- 20mA) and 14 digital channels for data registration. The system

is very flexible since the ADAM modules' upper and lower bounds,

alarm bounds and designations can be changed "on-line".

Advantech

ADAM modules are used in this data acquisition and monitoring

process. The analog and digital signals from the sensors are fed

from the tunnel over an RS-485 bus system to the monitoring PC.

The length of this RS-485 bus can extend up to 2.5 km and repeaters

are necessary. Two ADAM-4017 analog input modules and two ADAM-4052

digital input modules are used for data acquisition, and two ADAM-4510

repeater modules spaced approximately one kilometer apart are

used to give the RS-485 signals the necessary range. The data

acquisition modules are located close behind the drill. The RS-485

bus is a simple twisted pair of wires, which is pulled tight behind

the propulsion press, together with the telephone line. The measured

values are registered, archived and logged using the process visualization

software WinLab/E, both during the drilling operation and in the

stop mode. WinLab/E is a product of the German software company

Graf Elektronik Systeme GmbH. The system uses 16 analog channels

(4- 20mA) and 14 digital channels for data registration. The system

is very flexible since the ADAM modules' upper and lower bounds,

alarm bounds and designations can be changed "on-line".