China Railway High-speed Maintenance System

Project Introduction:

One of the best indicators of China's rapid economic growth should be transportation construction, especially concerning high speed rail projects. China is not only to adopt foreign systems but also invests a lot of efforts in trying to develop their own systems.

In 2007, with many years of experiences of railway rolling stock maintenance and repair, Beijing Railway Institute built its maintenance system for China Railway High-speed (CRH) including CRH Electric Multiple Unit Safety Monitoring System and the rail power system testing which is called the CJK-I Type Rigidly Movable Contact Net. Both of the systems are developed for the maintenance and repair tasks of trains and already have installed in many branch plants of Beijing Railway Institute.

|

|

System Requirements:

In the Wuhan factory, the inspection was carried out in a large warehouse (400x120 meters) through the programmable logic controllers (PLC) to collect signals and the data will be transmitted to the computer in the control room as well as being displayed on two different size LED monitors. There are a list of unique parameters that our client needed to be specified in the hardware specification including wide temperature range, anti-vibration, anti-interference and stable operation. Meanwhile, the Monitoring System requires a high performance IPC with Dual-Core CPU to meet the need for a 24 hours non-stop operation. The low power consumption is a basic demand for the CJK-I power system testing.

Project Implementation

:

| UNO-2182 |

Intel® Core™ 2 Duo Automation Computer with 2 x GbE, 4 x COM ports, DVI |

| UNO-2173AF |

Intel® Atom™ N270 Automation Computer with 2 x LAN, 3 x COM ports, and Mini PCIe |

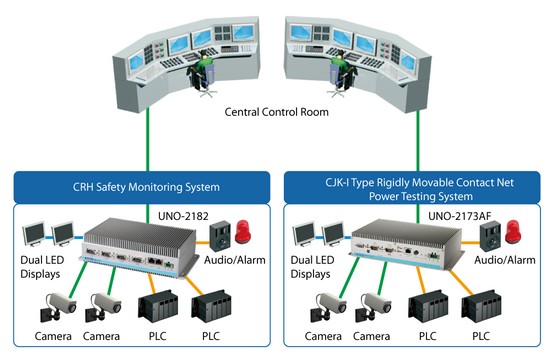

System Diagram:

System Description:

Because the CRH Safety monitoring system must continuously operate for 24/7 and requires a large amount of data processing, the robust UNO-2182 with Intel® Core™ 2 Duo processor is the best choice as the system host needs to manage the PLC and other peripherals on site. On the other hand, Energy Star certified UNO-2173AF with Intel® Atom™ N270 processor was chosen for the CJK-I Type Rigidly Movable Contact Net power testing system, which requires only basic computing and data processing. In both monitoring and testing systems, data acquired from PLCs is transmitted to the UNO-2182 and UNO-2173AF to dynamically display the status, parameters and curve of the various devices including signal lights, LED monitors, operating room indicator lights, and audible and visual alarms via a graphical user interface that allows users to easily interact with devices via image commands. In addition, the UNO-2182 and UNO-2173AF send alerts via the integrated speaker to warn staff when abnormal situations are detected.

Furthermore, the fanless UNO-2182 and UNO-2173AF are designed for harsh environments, which make them ideal platforms for maintenance sites with high temperatures and 24/7 non-stop operation. Their wide operating temperature range of up to 70°C, anti- interference, anti-vibration, and duel Ethernet ports ensure their reliability and stability. Both of them not only meet our customer’s specifications but also provide the best quality.

Conclusion:

Advantech’s Embedded Automation Computers have always provided customers with high-performance application ready platforms as well as high efficiency. Regarding the UNO-2100 series, their robustness and reliability make them excellent choices for harsh environment applications. |