A Simple Solution for Machine Vision

As we know, machine vision inspection is the most efficient way to speed up production but the high entry costs and large space requirements are two major obstacles in the way of manufacturing automation. Advantech’s PPC-6150A/6170A have been designed to conquer these problems by combining high computing power and multiple I/O ports.

As the factory begins its daily production, the components are being continuously assembled to fulfill the orders of worldwide customers. The global manufacturing industry has gradually set off a wave of robotization due to the rising demand in shipping timeliness and the optimization of the production process. In the meantime, growing labor costs and error-prone manual work has pressured more and more manufacturers to begin to seeking opportunities that will transform their automated manufacturing.

In the entire production process, the product yield is heavily dependent on the degree of perfection of basic parts, and the most crucial part is detecting defects in individual components because any minor flaw doesn’t only affect the quality of a single product but do greater harm to the brand value. Based on this, major manufacturers have began using machine vision inspection systems for quality assurance levels. Automated factories are using high-performance intelligent cameras collocated with industrial PCs as the computing core in most applications. Supplemented with visual image processing software, machine vision defect determination is finally been realized. Operators can then artificially monitor and perform operating settings by using other HMI devices located in third place. The consequence of such evolvement is that the artificial inspection or machine vision inspection with merely simple logic computing can’t fulfill the demands anymore. Meanwhile, minimized production equipment also significantly lowers the plant construction costs and manufacturers now are able to use leaner footprints to reach higher productivity. Under this condition, the original combination of smart cameras plus computing chassis plus HMI is now deemed to be unable to achieve the goal of device simplification.

Advantech is now offering a powerful and integrated machine vision computing platform—PPC-6150A/6170A- to overcome this problem. This product combines an Industrial PC’s powerful computing capabilities and a panel PC’s intuitive operation, the integrated design concept also means that it can accommodate a variety of installation methods and contributes a considerable benefit in space-saving. Its built-in Intel 3rd Gen Core i5 processor enables the

|

PPC-6150A/6170A to perform efficient and accurate judgment when executing the machine vision inspection procedure. This range of processors are all equipped with highly efficient graphics computing capability which can support two independent displays, this feature also provides a high degree of flexibility in on-site operation and the modification of a multi-function interface in order to achieve the best field vision machine combined with the key element of the whole system—smart camera.

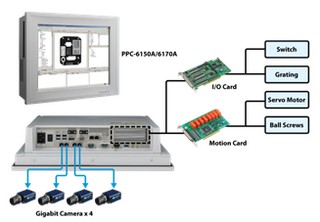

Advantech’s PPC-6150A/6170A offers four GbE LAN ports with built-in server grade internet chip (Intel i350) which provides a sufficient and stable pipeline for graphical information. It can inspect multiple parts of the production line simultaneously due to each LAN port being able to connect to separate cameras, and this has greatly improved the efficiency of the whole production line. This series also includes two PCI or PCIe x1 expansion slots, for users to use different expansion cards such as: motion card, I/O card…etc to meet their various requirements. Such a flexible design makes the PPC-6150A/6170A a perfect fit for a range of different industries.

|

In terms of safety, this model is equipped with an isolated RS232/422/485 port to avoid abnormal electrical surges which might cause system crashes that shut down the entire production line. In addition, it also supports Intel RAID technology which can be used to install two independent HDDs for data storage redundancy.

Advantech always thinks about the value that our products can deliver, and this is why the PPC-6150A and 6170A have been designed to adapt to the future trends of the manufacturing industry. Obviously, the all-in-one design brings not only a significant amount of space saving but also the cost saving of equipment procurement. Under the original structure, manufacturers need to set up a chassis for the computing part of the whole system and an HMI operating station or even an additional screen for test result monitoring. We can expect the financial burden from decentralized equipment purchasing will be heavier than a multi-tasking machine i.e. the PPC-6150A/6170A; not to mention the complexity of the wiring arrangement of decentralized devices. In the unstoppable trend of automatic production, Advantech’s PPC-6150A/6170A is ready to serve the demand and it is sure to be a pioneering model. |