Centralized Heat Supply & Exchange System

Building Automation

Beijing, China

|

|

Project Introduction:

A central heating system provides warmth to an entire building from one point to multiple rooms. Centralized heat supplies are an important part of energy-saving in any large building, and one of the main basic infrastructures of urban modernization. Heat supply systems mainly include heating stations a complete water pipe network, heat exchange station, and more.

|

System Requirements:

A large residential complex in China turned to Advantech for help setting up a comprehensive heat supply and exchange system with monitoring capabilities, control, and remote functionality. They wanted to be able to monitor and control the following aspects of their system:

- Inlet and outlet water temperature & pressure of the primary pipeline

- Inlet and outlet water temperature & pressure of the secondary pipeline

- Water flow in the primary network of the heat exchange station

- Details on activity in the circulation pump and pump transducer

Project Implementation:

|

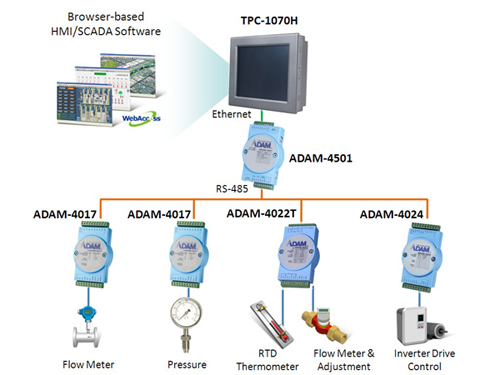

TPC-1070H |

10.4” SVGA TFT LCD Celeron M Touch Panel Computer |

|

WebAccess |

Browser-based HMI/SCADA Software |

|

ADAM-4501 |

Ethernet-enabled Communication Controller with 8 x DI/O |

|

ADAM-4017 |

8-ch Analog Input Module |

|

ADAM-4022T |

2-ch Serial-based Dual Loop PID Controller with Modbus |

|

ADAM-4024 |

4-ch Analog Output Module with Modbus |

System Diagram:

System Description:

The heat supply system of residential community includes the water pipe network and heating station. The pipe network is further divided into primary and secondary networks, with the former referring to the pipeline network between the urban pipeline network and heating station while the latter referring to the pipeline network between heating station and community itself.

The control room meters and controls devices connected to the primary and secondary networks for heat exchange, heat dispatching, system monitoring and adjustments. As shown in the system diagram, ADAM-4017 is used with flow meters and pressure meters to detect flow rate and pressure variation. ADAM-4022T measures temperatures through an RTD thermometer and adjusts the flow rate with PID functions. ADAM-4024 can be used to control the inverter drive. All of the ADAM devices can be monitored with Advantech's WebAccess SCADA software.

This system is used to adjust and maintain heating parameters (voltage, temperature and flow) to guarantee the heat supply runs safely and economically, therefore, functions and features of heat exchange automotive control system are very important; the monitoring and controlling core is for primary and secondary networks’ inlet and outlet water temperature, voltage, flow, conditions of circulation pump and make-up water pump, start and stop control, spin speed, malfunctions, electric quantity and other parameters. To improve the operating efficiency and management quality, the heat supply dispatch department needs to conduct centralized and real-time monitoring of temperature, voltage, flow, liquid levels, device conditions and many other parameters of the distributed heat exchange stations, remote control of the running of devices in the heat exchange station.

Conclusion:

After implementation, the management staff of the residential complex was able to achieve complete monitoring and control for both the primary and secondary networks in the heat exchange system. This allowed them to provide their community with improved service while increasing their energy saving and efficiency by a large margin. |