A Total Automation Solution for Fiberglass Textile Machines

Project Introduction:

Due to its superior attributes like: strength, flexibility, durability, stability and being light-weight fiberglass is the most common reinforcing element used in commercial and industrial composites. As a result, high-speed textile machinery and automated production lines have become necessary measures to meet market demands. However, textile machinery automation should not stop at solving the problem of quality. The question of how to reduce the human cost and enhance management effectiveness are increasingly prominent objectives. By implementing Advantech’s total automation solution, including software and hardware, fiberglass textile machines are no longer stand-alone automated equipment but also leverage the features of network connectivity and data processing to provide real-time troubleshooting and increase productivity as well as helping users collect on-site data for processing quality and capacity analysis so as to optimize the production process.

System Requirements:

One of Southeast Asia's largest fiber glass manufacturers, which is principally engaged in the manufacture and distribution of electronic-grade fiber glass yarns, industrial fiber glass yarns and electronic-grade glass fiber cloth for reinforcement and insulation materials in printed circuit boards (PCBs) was planning to raise the level of automation in production so that administrator can keep abreast of the production status while reducing handwriting errors. Although, the system integrator can provide automated textile machinery, the lack of integration makes relevant information access and analysis more difficult for managers to make sound decisions that are based on real-time information and complete records.

In order to replace the original individual operating mode, the new system has to offer a total solution, including a friendly user terminal for textile machines to easily control the manufacturing processes, the reliable network connection to ensure accurate data transmission, a powerful computer for the control center as a server to deal with large amounts of data. Apart from various devices, the HMI runtime development software was needed to quickly design a suitable user interface for textile machinery and industrial panel PCs was also a necessity for this case.

System Description:

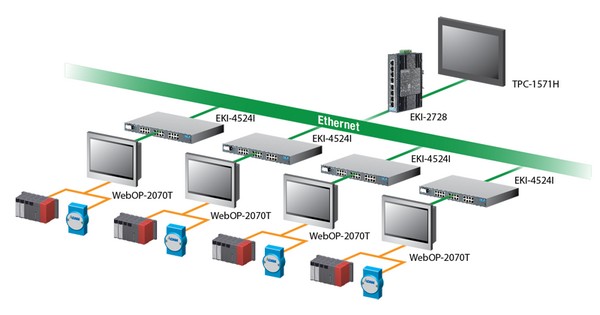

A total of 84 Advantech WOP-2070T, 7" WVGA Operator Panels, were installed on the production lines to collect a variety of signals from on-site devices such as PLC, driver and stepper motor and this data can be transmitted to 15" Touch Panel Computers (TPC-1571H) in the control center via the two kinds of Ethernet Switches (EKI-4524 and EKI-2728).

The WOP-2070T provides an outstanding price performance ratio such as built-in ARM9-based RISC processors and up to 200MHz and 128MB flash memory as well as supporting hundreds of industrial communication protocols and a diverse range of communication interfaces to connect to a variety of devices. By being embedded in the fiberglass textile machine, it is not only used as an HMI for operators to easily control production operations by their fingertip but is also a communication gateway to upload and download real-time data without additional programming. In addition, they were bundled with WebOP Designer 2.0 which is a software development kit and offers various features, including solution-oriented screen objects, high-end vector graphics, recipes, alarms, data loggers and operation logging, online/offline simulation and other utility programs can help developers to effortlessly create applications with simplified architecture using a few steps.

In terms of the network transmission, both of EKI Ethernet Switches can guarantee a stable communication quality thanks to an excellent design. For example, the 24-port EKI-4524 has wide range of voltage power input and provides a convenient and uninterrupted power supply. The 8-port EKI-2728 supports: Gigabit Ethernet and has a redundant power input, power polarity reverse protect and overload current resetable fuse to make sure that devices will not be damaged and system can always operate normally and smoothly.

As a server in control center, the TPC-1571H with an Intel Atom Dual-Core processor and built-in I/0 for multiple system connectivity is responsible for handling a lot of data, e.g. manufacturing order, machine speed and utilization rate, while instantly displaying the status of textile machines through SCADA software. If an abnormal condition occurs, an alert will be shown on the screen and the system will send warning message as well, and therefore the manager has no need to stay on the factory floor but can fully control the production operations from wherever they may be. Besides which the, PanelExpress 2 which is a Windows based HMI runtime and equips with the configuration software - WebOP Designer, enables users to utilize the resources of a PC and realize the high-end sophisticated HMI. Compared to traditional SCADA software, PanelExpress offers a cost-effective method to integrate thousands monitoring points; thus to control on-site machines in real time.

Project Implementation:

| Product |

Description |

WOP-2070T |

7" WVGA Operator Panel with WebOP Designer 2.0 Software |

EKI-2728 |

8-port Gigabit Unmanaged Industrial Ethernet Switch |

EKI-4524 |

24-port Ethernet Switch with Wide Temperature |

TPC-1571H |

15" XGA TFT LED LCD Intel Atom Dual-Core D525 Touch Panel Computer |

Panel Express 2 |

Windows based HMI runtime |

System Diagram:

Conclusion:

In intense competition, the system integrator must propose solutions that differentiate to win customers. Advantech’s total solution not only helps system integrators develop a brand new automation system from the stand-alone operation to an integrated solution but also allows users upgrade its management efficiency from passive maintenance to active management while reducing labor and management costs. Through the database, Advantech’s solution even allows administrators to analyze its process work and quickly prioritize process improvement initiatives. With a successful outcome, the customer is pleased to further implement this solution in other factories.