The oil and gas industry is still at the heart of the world’s energy supply. From exploration and development, drilling and production, to fuel transportation and processing, creating reliable, efficient and accurate monitoring and control systems is important for every stage of the oil & gas industry. These applications are still some of the most dangerous and demanding of any industrial application, and require rugged and reliable products to ensure safety and efficiency.

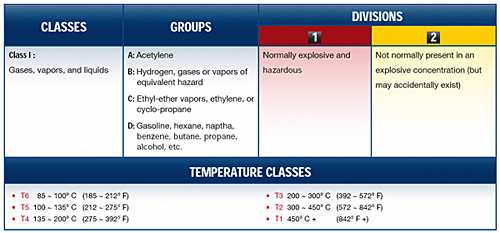

In order to fulfill requirements of product which are in Hazardous locations, the 1999 U.S. National Electric Code (NEC®) and the 1998 Canadian Electric Code (CEC®) now recognize the use of the Zone system for classification of hazardous areas and define the certification for use in Hazardous locations.

Certification Definition - Class I, Division 1 & 2

Hazardous locations are areas where potential hazards (e.g., fires, explosions, etc.) may exist under normal or abnormal conditions because of the presence of flammable gases or vapors, flammable liquids, combustible dusts or ignitable fibers. According to the NEC (National Electrical Code), there are three types of hazardous locations categorized by three classes: Class I (gases, vapors, and liquids), Class II (dusts), and Class III (fibers and flyings). Division 1 means normally explosive and hazardous and Division 2 means not normally present in an explosive concentration but may accidentally exist.

Class I is directly related to the oil and gas market applications, such as petroleum refineries, gasoline storage, dispensing areas and utility gas plants. According to the ignition temperature of the substance, its explosion pressure, and other flammable characteristics, the gases and vapors of Class I locations are broken into four groups by the Codes: A, B, C, and D. Temperature classes also exist to designate the permissible surface temperature of electrical equipment which allows them to operate normally in the surrounding atmosphere.

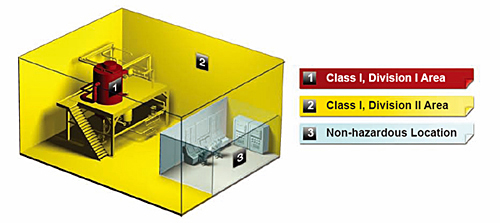

Hazardous and Non-hazardous Locations

Below is a conceptual diagram of Class I, Division 1 & 2 hazardous areas and non-hazardous areas.

Advantech’s Certified Products & Solutions

Advantech leverages over 25 years experience in the automation industry to design different product offerings and solutions for reliable use in hazardous locations. Advantech has designed a series of products which have passed Class I, Division 2 Groups A, B, C, D certification, and Temperature class is at least T4 (135~200°) which means these products can to operate normally in a surrounding atmosphere of 135~200° C. The product offering includes: Human Machine Interface, Industrial Communication, Embedded Automation Computers, and Data Acquisition modules.

Industrial Monitors and Controllers

Carrying industrial automation technology into the oil and gas industry, Advantech offers industrial monitors;, the FPM series;, two categories of automation controllers including embedded automation computers, ; the UNO-1100H series, ; and Programmable Automation Controllers, the APAX series, to fulfill various application needs. Both the FPM and UNO-1100H series have passed Class I, Division 2 Groups A,B,C,D certification, which extends use to hazardous applications. The UNO-1100H series is fanless, with no internal cabling and no moving parts, with a wide power input range and dual Ethernet to assure reliability and security. The APAX-5000 series integrates control, information processing and networking in a single controller, which support powerful control systems and is suitable for non-hazardous location applications.

Human Machine Interface

– FPM-8151H Series |

Embedded Automation Computer

– UNO-1100H Series |

Programmable Automation Controller

– APAX-5000 Series |

|

|

|

Industrial Communication - Product Family

|

Industrial Communication

Advantech provides interconnected solutions with Industrial Networking, Device Connectivity, and Industrial Wireless Technology. With industrial-grade product design, Advantech’s ICOM products have passed the harsh tests of various vertical markets, such as: IEC 61850 for substation automation, EN50155 for railway automation, and UL508 safety for industrial control equipment. In order to fulfill the connecting needs of hazardous applications, Advantech offers a comprehensive range of UL approved Class I, Division 2 Groups A, B, C, D industrial communication solutions, including Industrial Ethernet Switches, Media Converters, Serial Device Servers and Modbus Gateways.

|

Data Acquisition – ADAM Family

|

Data Acquisition Modules

Advantech’s FM approved remote I/O modules, including repeaters, converters, and both RS-485-based and Ethernet-based remote data acquisition modules, provide ideal industrial automation, control, and measurement solutions for confronting harsh environments and demanding applications. What’s more, with wide operating temperatures and multiple mounting methods, Advantech’s ADAM series can be implemented in diverse applications, making the system always connected and reliable. Besides, Advantech’s ADAM-3000 series consist of very cost-efficient, field configurable, isolated signal conditioning modules that can be easily installed to protect instruments and process signals from the harmful effects of most electrical interferences. |

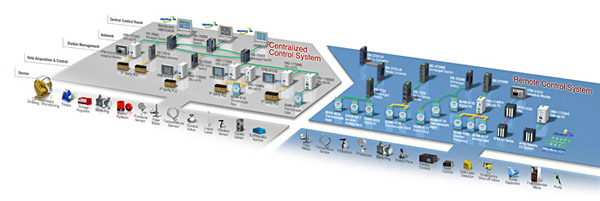

Advnatech’s CID2 certified product solutions are well suited to fitting the demanding requirements of various oil and gas applications, such as oil field drilling, pump station monitoring, oil pipeline monitoring, tank storage monitoring, and fueling station management. Furthermore, Advantech’s standard product offerings can be used in non-hazardous locations, such as facility control and management for the oil and gas industry. Advantech is always your best component partner to go into vertical markets.