| |

Operator Panels Integrated with Controllers Fulfill

Process Control Optimization

|

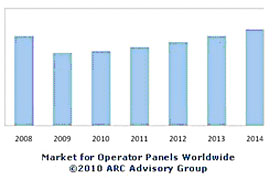

Industrial automation companies are finding that an increasing amount of customers prefer purchasing broad solutions packages from one supplier or system integrator so that they can ensure the products work seamlessly together, as well as only having to turn to one company when they need repair or customer service. Therefore, many suppliers are trying to expand their offerings to provide total solutions in many diverse markets, such as automotive or steel processing. One of the key components to any automation solution is always the interface, which provides operators a means to control all of the interconnected devices in their systems. A recent ARC report shows that operator panels have the largest dollar volume growth of any industrial product over the forecast period through 2013.

|

ARC Research, January 8, 2010, Market for Operator Panels

ARC Research, January 8, 2010, Market for Operator Panels

|

They note that the market for operator panels is divided into two parts: Suppliers that offer the panel plus controller business and suppliers that sell operator panels alone. As mentioned earlier suppliers that can find a way to bundle panels and controllers together can expect to experience a higher volume of sales than suppliers that only offer individual components, as customers would like to have a total solution that combines operator panels with controllers to optimize their systems for long-term use. To expand this total business solution further, operators require flexible connectivity so that they can connect new generation PACs as well as PLCs for applications that require higher-level process control, as this architecture ensures high reliability for critical control tasks and satisfies users in need of high performance solutions for complex control applications.

Advantech’s latest line of operator panels (WOP series), is highly compatible with its programmable automation controllers and remote data acquisition I/O modules, which allows customers to build three kinds of different data acquisition and control solutions for versatile applications.

|

|

1. |

Remote Data Acquisition System with HMI

Advantech APAX I/O modules features scalable and flexible architecture, hot swap capabilities, high density I/O and expands to include up to 32 modules (up to 1536 points), which can fulfill requirements in space limited cabinets or machinery. Through APAX-5070 couplers, any HMI platform can easily communicate with APAX I/O modules through industrial standard Modbus/TCP protocol, to develop reliable and remote data acquisition systems. |

| 2. |

Control System with HMI

In a general control system, operator panels are able to connect with PLC control systems to deal with electromechanical automation tasks, such as machinery control on factory assembly lines or process control. For expanding I/O in existing PLC systems, Advantech provides coupler modules (APAX-5070/5071/5072) which can connect APAX I/O with PLC, through different protocols, such as Modbus/TCP, Profinet and EtherNet/IP. PLC users can simply leverage APAX I/O with original PLC development software. The existing PLC system can easily increase the flexibility and scalability through APAX-5000 remote I/O system. |

| 3. |

Advanced Control System with HMI

In highly complex control systems, where high computing power, networking capability and time-deterministic I/O are necessary, Advantech’s APAX PAC features integrated I/O control, data logging and analysis, information processing, networking, audio and video functionality, which can deal with multiple domain applications. Advantech provides operator panel plus PAC series, either compact PAC (APAX-5520 series) solutions, building up stable automation control systems for mission-critical applications.

|

It’s easy to integrate operator panels into systems since software plays an increasingly important role. To further the pursuit of delivering solutions that meet the needs of panels with built-in control functionality to fulfill process control optimization, Advantech provides an innovative and integrated platform based on performance, technology and design, the WOP-2000 series which comes bundled with powerful HMI runtime development software: PM Designer 2.0. The software is proven in many application fields and is an easy to use integrated development tool featuring solution-oriented screen objects, high-end vector graphics, Windows fonts for multi-language applications, recipes, alarms, data loggers and operation logging.

Most operator panels are limited to “interface” capabilities of monitoring and operating, while Advantech’s Operator panels are strategically focused to be combined with powerful Programmable Automation Controllers to fulfill process control optimization.

|

Related Product Highlights -

| HMI |

| WOP-2000 Series |

Operator Panel with PM Designer 2.0 Software |

| Controllers |

| APAX-5520KW |

Micro PAC with XScale CPU |

| Couplers |

| APAX-5070 |

Modbus/TCP Communication Coupler |

| APAX-5071 |

Profinet Communication Coupler |

| APAX-5072 |

Ethernet/IP Communication Coupler |

| Analog I/O Modules |

| APAX-5017 |

12-ch Analog Input Module |

| APAX-5028 |

8-ch Analog Output Module |

| Digital I/O Modules |

| APAX-5040 |

24-ch Digital Input Module |

| APAX-5045 |

24-ch Digital Input/Output Module |

| APAX-5046 |

24-ch Digital Output Module |

| APAX-5060 |

12-ch Relay Output Module |

| Backplane |

| APAX-5001 |

1-slot Backplane Module |

| APAX-5002 |

2-slot Backplane Module |

|

|

|

Copyright © 1983-2010 Advantech Co., Ltd. All Rights Reserved. |

|