A robust panel PC for intelligent tightening machine in an automobile assembly factory (Shandong Chunlong Group)

Project Introduction:

Project Introduction:

As China becomes one of the world’s largest auto markets, the relevant manufacturing industries are also booming; leading to a strong demand for highly accurate manufacturing machines. During the assembly process in an automotive plant, bolt tightening is a critical task to ensure car safety and needs to precisely control torque and rotation angle. Its tightening speed also has to be adjusted according to softness and hardness of bolt material as well as a degree of fitting tightness. Compared to manual operation, automated machines can provide more precise control and can even upgrade to intelligent applications by using advanced IT technologies so as to reduce human error and improve productivity. However, the quality of the Human Machine Interface (HMI) affects the machine’s performance, resulting in industrial panel PCs being indispensable in ensuring stable system operation.

System Requirements:

A Chinese company in Shandong is devoted to the solution of modernizing industrial assembly lines and intelligent tightening machines (also called bolt screwing machines) is one of its main product offerings. In order to meet users’ strict assembly requirements, this System Integrator was planning to upgrade its product and intended to use an all-in-one industrial panel PC to replace the previous large and slow computer and monitor. Since the operating environment is more stringent in an automobile assembly factory and is filled with a variety of pollutants which often cause computers to frequently shutdown or crash, the new PC must have better resistance to vibration, dust, humidity and electromagnetic interference. They also required that the unit had a rugged design to protect the front panel since most of the workers are accustomed to using tools to touch the monitor instead of their fingertips. The customer also needed a PCI slot to connect with various devices and front USB access to facilitate software updates or on-site data storage without opening the unit.

System Description:

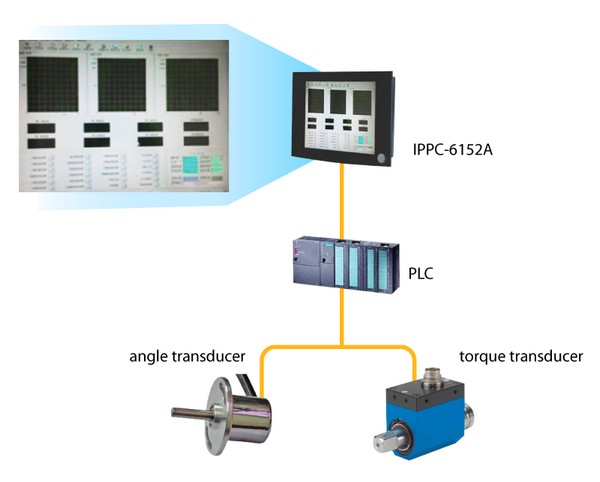

Based on these system requirements, Advantech proposed a sturdy and durable IPPC-6152A with two expansion PCI slots and external communication cards to connect to a PLC, enabling the tightening machine to accurately control angle transducer and torque sensor by default values, and all sorts of parameters can be easily monitored and changed directly through touch. The IPPC-6152A is equipped with a 15" LCD screen which offers a high resolution display and lightweight design to provide the most suitable viewing angle and user friendly HMI for operators. For the sake of hardware robustness, its front panel is IP65 compliant and made of sturdy aluminum and has strengthened glass. It also provides a front USB access port and reset key for effortlessly connecting other devices or configuration without removing the rear cover. Due to overheating concerns and reliability issues, the IPPC-6152A, which is installed in the machine cabinet, supports a wide operating temperature range of 0~50°C, dust and moisture resistance, vibration protection and anti-interference via the use of a CE-compliant metal enclosure to guarantee system stability during prolonged operation.

Project Implementation:

| Product |

Description |

| IPPC-6152A |

15" XGA TFT LCD Core 2 Quad / Core 2 Duo Industrial Panel PC with 2 x PCI Slots |

System Diagram:

Conclusions:

By implementing automated or intelligent machines to improve manufacturing processes is an inevitable trend of industry development. With a rugged design, fine texture and high reliability, Advantech’s IPPC-6152A can not only satisfy demanding applications but also has better cost-effectiveness than competitive products, enabling the System Integrator to seamlessly integrate its hardware and application software and provide a high precision and excellent machine for end users. Additionally, Advantech’s perfect after sales services and technical support also fulfill customers’ various requirements and help them quickly complete their project so as to create a superior competitive advantage.