External Rotor Stator Winding Machine

Machine Automation

Location: China |

|

Project

Introduction:

A stator is the stationary part of a rotor system, such as in an electric generator or electric motor. External rotor stator winders are used for automated coil winding in the manufacturing of such devices, such as portable electric tools, small electric generators, and electromotors in vehicle engines. This external rotor stator winding machine was built with the help of Advantech, combining motion control and HMI to provide animated displays and self diagnostic functions. |

System

Requirements:

The goal of this solution was to create a stable and high performance stator winder with a robust computing controller and easy to use interface. Advantech knew the key to this project was to integrate stationary fixtures and hook line protection devices to ensure quick installation of the enameled wire hook, helping realize accurate auto tension control and the ability to store and reference data regarding the rotor winding process.

Project

Implementation:

|

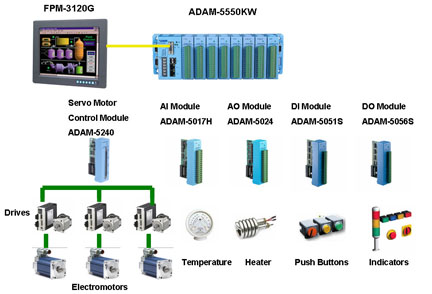

ADAM-5550KW |

8-slot Programmable Automation Controller |

|

ADAM-5017H |

8-channel High-speed Analog Input Module

|

|

ADAM-5024 |

4-ch Analog Output Module |

|

ADAM-5051S |

16-ch Digital Input Module |

|

ADAM-5056S |

16-ch Digital Output Module |

|

ADAM-5240 |

4-axis Stepping/Pulse-type Servo Motor Control Module |

|

FPM-3120G |

Industrial 12.1" SVGA Flat Panel Monitor |

System

Diagram:

System

Description:

At the heart of this system is Advantech’s ADAM-5550KW controller, which is able to connect and control various system devices, such as control buttons, indicators, temperature meters, production data storage, variable frequency motors, etc… ADAM-5550KW also provides animated displays and self diagnostic functions, which reduces labor intensity and helps increase production efficiency and quality as well.

For the HMI display, the FPM-3120G touchscreen monitor enables users to easily edit, modify, store and encrypt coil data. The system supports rotors of different models, realizes complicated coil winding via multi-axis motion control and meets the requirements of mass production. Furthermore, the programming software is compliant with PLC Open, making it much easier to learn and operate. Various coil winding processes are integrated to realize complicated data processing with the help of the high-speed computing performance of the ADAM-5550KW.

Conclusion:

The automatic stator winder uses Advantech’s ADAM-5550KW to meet diverse requirements with strong computing capabilities and large data storage. In addition, the intellectual property of the customer’s manufacturing process can be protected with the help of the copy-protect function in the embedded system. As a result, labor intensity has been reduced, while production efficiency and quality has been greatly increased.

|