Disaster Prevention and Safety Monitoring System for High-Speed Railway

Project Introduction:

High-speed train runs at speeds of 300-350 kilometers per hour and in order to ensure the safety of passengers, building a disaster prevention system is essential to reduce potential accidents.

|

|

System Requirements:

Railway accidents in Asia have often been caused by mudslides and a lack of alarm systems mean that drivers unwittingly keep the train moving.

In order to ensure traffic safety, the whole monitoring system for railway application is required to comply with stringent standards. At the first, the monitoring system must be in continuous operation for 365 days and be able to communicate through a variety of serial transmissions, whilst also needing an anti-static and fanless design to make sure the system works correctly. The main system is set in the train station or the system cabinet and the receptors and sensors will be set next to the railway lines. Through the receptors and sensors, signals can be transmitted to the host so as to know the situation along the railway line e.g. rain, snow, wind and other conditions.

Project Implementation

:

| MIC-3001 |

4U CompactPCI® Chassis with 8-slot 3U Backplane |

| MIC-3321C |

3U CompactPCI® Pentium M 2.0 GHz CPU Card |

| MIC-3756 |

64-ch Isolated Digital I/O 3U CompactPCI® Card |

MIC-3611

|

4-port RS-422/485 3U CompactPCI® Card with Surge and Isolation Protection |

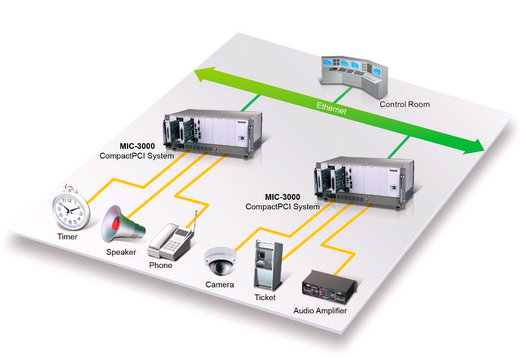

System Diagram:

System Description:

Based on the communication framework, Advantech's disaster prevention system for high-speed railway, CompactPCI platforms integrated acquisition, analysis, and processing to support driving safety. The platforms are widely used for mission-critical telecommunication applications that demand high-serviceability, enhanced reliability, and vibration/shock resistance. Integrating the latest technologies, the platforms offer rugged design, durability, hot-swapping and compatibility with all Computer Telephony (CT) Buses.

Advantech's data acquisition cards collect the on-site data from the receptors and send it to the host through RS-485 whose longest distance of data transmission can be 10km. The data collect includes earthquakes, rainfall, flood, wind, track temperature, engine room temperature etc. With a metal chassis, Advantech’s CompactPCI offers the best electrostatic protection; meanwhile, its hot swap feature enables the board to be replaced in 10 seconds without shutting down the system. Compared with PLC products, CompactPCI’s can complete customer’s complex needs with a single and integrated solution. It not only provides A/D acquisition but offers a variety of serial ports without the extra hardware.

To ensure continuous operation, CompactPCI provides two sets of systems in one chassis, both computers work independently with exactly the same specifications: CPU, power supply, communication cards, and data acquisition cards, when one system crashes the other one can immediately take over the operation to eliminate the doubt over downtime. Besides, Advantech’s thermal technology and low power consuming components enable the CompactPCI to work in extended temperature ranges (-20~70°C/ -4~158°F) without a fan.

Conclusion:

In modern society, high-speed rail brings huge benefits to the regional economy. However, preparing for traffic safety is a critical factor for success. Through advanced technology, Advantech’s disaster prevention system offers the suitable features with the best stability and performance to help the high-speed railway to monitor all situations around its rail road. In addition, Advantech’s solution is effective in reducing the risk of crashes, viruses, and misuse as well as significantly reducing CPU usage and eliminating the problem of overheating via the embedded operating system - Windows XP Embedded. Furthermore, Advantech’s local R&D engineers and support teams can provide the best services to meet the customer needs. All these advantages have made our products the excellent choice for this application. |