The multi-factory and cross-system integration solution

Project Introduction: Project Introduction:

As manufacturing companies expand and leverage their scale and manufacturing capacity, one of their major challenges is to achieve greater operational efficiency, but most of companies have numerous, complex and critical systems within their plants to manage scheduling, production, inventory and quality data, especially if they own several factories around different cities which makes management more complex. Therefore an easy and effective way to supervise each factory and sharing information across multiple sites is what they need most. By using Advantech’s integrated solution to provide cross-system integration, unified interface, real-time data collection, and visualized monitoring platform, factory managers can actively ensure the delivery of quality products in a timely and cost-effective manner.

System Requirements:

Our customer mainly engages in designing, developing, producing and the sales of printed circuit boards (PCB), and is a major global PCB supplier. It has four manufacturing sites across China, in Shenzhen, Huai'an, Qinhuangdao, and Yingkou that respectively focus on different products manufacturing and have a variety of systems for production operation management. As a result, these sub-systems has failed to effectively aggregate the required data for the headquarters needs and the different communication interfaces in each factory also add to the difficulties of integrating the existing systems.

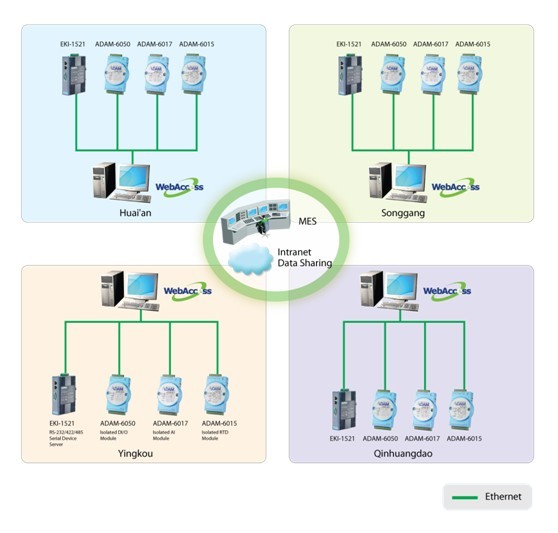

Therefore, the customer began surveying graphical monitoring control software as its new platform to perform the cross-system integration in order to facilitate the production control of all factories in real time. The four manufacturing sites have already implemented many PLCs with their own communication architecture to gather on-site data, but there are still some inadequacies that need to be improved by Ethernet I/O Modules to expand their monitoring. The Serial-to-Ethernet gateway must also be upgraded to more powerful devices to guarantee network reliability.

System Description:

After the customer’s detailed assessment, Advantech WebAccess, a browser-based HMI/SCADA software, was chosen as an integrated platform for this multi-factory and cross-system application. Through its easy and convenient configuration, users no longer need to develop new drivers for PLC connections while it is capable to linking to various kinds of PLCs or devices no matter what vendor provides. Unlike closed systems that are difficult to be integrated into or with other systems, Advantech WebAccess is an open platform and offers perfect functionality to integrate multiple systems and protocols. Additionally, all of the data from the bottom layer up can be displayed on monitors in a graphical form or can be shown on a scheduled report. Other features of Advantech WebAccess, including real-time data control, alarms by email or short message alert, the provision of development tools, etc. provide additional benefits.

As for the data acquisition device, Advantech offers ADAM-6000 series modules (ADAM-6050, ADAM-6017, and ADAM-6015) to collect the on-site signals, making user can remotely monitor the temperature and humidity of factory environment as well as supervising the conditions of equipments such as oven current, production machine counter, and warning light. This project firstly adopts ADAM-4571 to be a data gateway so that the existing devices can be seamlessly integrated with an Ethernet network. With the sustained increase in monitoring items, Advantech further proposes EKI-1521 which features two independent Ethernet ports and MAC addresses to provide a redundant network mechanism, and meanwhile to ensure the better transmission quality.

Project Implementation:

| Product |

Description |

| Advantech WebAccess |

Browser-based HMI / SCADA Software |

| ADAM-6050 |

18-ch Isolated Digital I/O Modbus TCP Module |

| ADAM-6017 |

8-ch Isolated Analog Input Modbus TCP Module with 2-ch DO |

| ADAM-6015 |

7-ch Isolated RTD Input Modbus TCP Module |

| ADAM-4571 |

1-port RS-232/422/485 Serial Device Server |

EKI-1521 |

1-port RS-232/422/485 Serial Device Server |

System Diagram:

Conclusions:

For many enterprises or manufacturers, moving towards multi-system integration is a big challenge but is also a future development trend for all of them. With Advantech’s hardware and software, this PCB supplier gains many advantages, including saving software license fees and development times, unifying the communication interfaces, integrating the existing systems and sharing more information and adding consumable reminders, plus a lot more. Our professional team also helped its IT engineers to resolve some crucial problems, enabling them to smoothly design and maintain their own system. Furthermore, the client also expanded its scope of multi-factory automated management from production and measurement to factory operation and access security control all because of Advantech’s easy, integrated, and complete solution. |