Transmission Testing System

Machine Automation

Beijing China

|

|

Project Introduction:

Transmissions are one of the most essential components of an engine, increasing and reducing engine speed by increasing torque. Transmissions are also used on bicycles, fixed machines, and anywhere else rotational speed and torque needs to be adapted. Often, a transmission will have multiple gears with the ability to switch between them as speed varies. In order to make sure that transmissions are suitable for the variety of conditions that drivers will encounter in everyday use, they must be thoroughly tested under the most strenuous conditions.

|

System Requirements:

This transmission testing program utilizes electromotors to simulate the engine and generators. Two AC motors will simulate vehicle conditions; then online test indicators will be monitored in real-time to provide a system performance curve. A manipulator will automatically complete the shifting actions for different gears and the control software will monitor will show operation parameters such as temperature, rotation speed, torque and current. The control section is a computer-centered unit, which can control system flow, task assignments, instructions and failure detection based on field data and current operation status.

Requirements for automobile transmission testing system included:

- HMI with good shock resistance and membrane keyboard, that supports dual displays

- Easy I/O expansion, with real-time operation

- Real-time control of temperature, rotation speed, torque, noise and speed

- The system should be able to withstand electric surges, oil, dirt and dust

Project Implementation:

|

AWS-8248 |

15" XGA TFT LCD Industrial Workstation with 14 x ISA/PCI/PICMG Slots |

|

PCI-1712 |

1 MS/s, 12-bit, 16-ch PCI Multifunction Card |

|

FPM-2150 |

15" XGA Industrial Monitor with Resistive Touchscreen and Direct-VGA Port |

|

ADAM-4017 |

8-ch Analog Input Module |

|

WebAccess |

Browser-based HMI/SCADA Software |

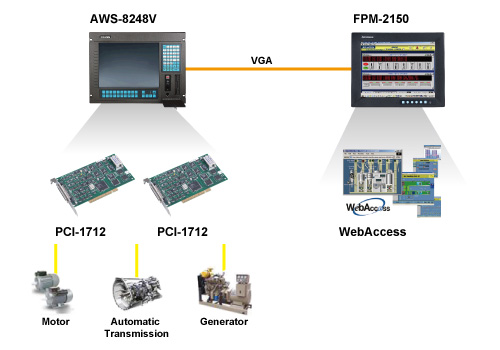

System Diagram:

System Description:

AWS-8248 is adopted to connect an industrial display and a data acquisition card (PCI-1712), so the display can be output to the central control room in real-time. PCI-1712 is used to control output parameters and realize actions, such as loading and shifting of the gear box. Meanwhile, it can also read gear box operation parameters, including temperature, rotation speed, torque and noise. What’s more, it can realize data recording and real-time monitoring with the help of WebAccess and send automated alarms as well as auto analysis.

Conclusion:

Advantech’s open integrated solution creates a complete automobile transmission testing system, which fulfills fast, precise and automatic real-time test requirements. |