Advantech’s ADAM Remote I/O Modules have been a consistent and reliable figure in the industrial automation field for almost 20 years. Although the core functions have remained relatively unchanged, Advantech’s research & development teams have constantly been analyzing and improving the ADAM series, with applied technology more advanced than its competitors. From the early RS-485-based ADAM-4000 series to the more recent Ethernet-based ADAM-6000 I/O series, Advantech has been developing technology ahead of the curve with advanced networking technologies.

Whether dealing with large or small systems, Advantech’s ADAM Remote I/O Modules can usually be found embedded somewhere as an integral keystone. These I/O modules support much larger interconnected systems with reliable functions and strong features. To celebrate the milestone of one million ADAM modules sold worldwide, Advantech would like to take a moment to share some background on this long-standing series of industrial products.

Design

Advantech’s ADAM module has had its sky blue signature color ever since it originated in 1992. Complimented with a bright green terminal, the ADAM module’s appearance brings a more fresh and approachable image into the traditionally gray-and-black industrial field. The initial design concept of ADAM focused on its ability to be recycled, marking Advantech’s efforts to be environmentally conscious as far back as 20 years. All of its housing and onboard terminals can be recycled and reused in fact. And each ADAM shipping box contains more than 80% post-consumer recycled fiber to help save the earth even more.

Technology

Advantech’s Development & Research team has always kept ahead of its customers’ needs, providing distinct solutions for different needs. ADAM-4100 series for example, has been improving on its functionalities and usability over many years. The ADAM-4100 robust series is based on the design of ADAM-4000 with reinforced isolation protection, wide operating temperatures and input power, strict environment applicability and watchdog communication.

When Advantech expected that networking would bring great change to the automation industry, we introduced the ADAM-6000 series, one of the first Ethernet-based data acquisition modules. And in the last half-decade the transfer speed of remote I/O became so demanding among users that Advantech launched the ADAM-6100 real-time Ethernet I/O solutions.

Installation

Advantech also emphasizes user friendliness, such as the convenience of installation and maintenance, as well as reliability and cost effectiveness. The modular industrial design enables ADAM modules to be easily mounted on a DIN-rail, panel or piggybacked on top of each other, depending on the customers’ requirements.

Quality

Each ADAM module is strictly tested by Advantech’s Production Engineers and Product Quality Controllers before it is shipped to the customer. To ensure quality unification and stability, Advantech not only dedicates on multi-dimensional approaches to test during production, but also avoids possible issues that may led to the defects in the first place. All ADAM Remote I/O Modules must pass a least five stages of examinations and different modules have different examination jigs, which are calibrated annually. Furthermore, modules must be packaged in antistatic bags, protecting against mechanical damage as well as electrostatic damage which can easily happen during shipments.

Conlusion

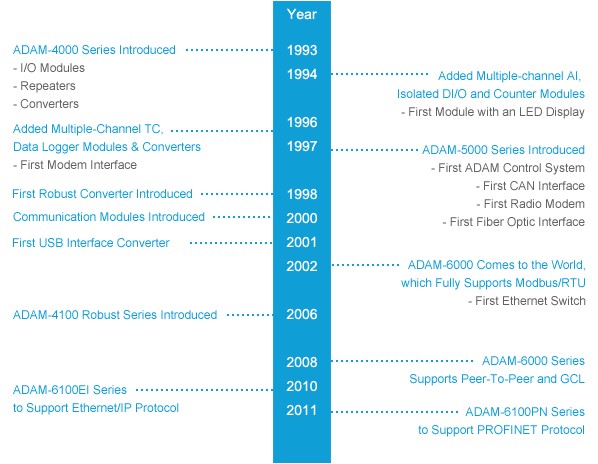

We have also included a timeline to outline the various milestones this ubiquitous series has achieved below. As you can see from its rich history, the ADAM series has continually evolved ahead of the curve, and has always strived to meet customer demands before they are even aware they need them. This trend is not one that has stopped however, and Advantech customers can expect to see many new technologies and innovations applied to the ADAM years for many years to come. Thanks for your continued support.

Timeline