Improving CEMS architecture with best performance

(ZheJiang Huanmao Auto-Control, China)

Project Introduction:

Project Introduction:

As industrial development brought economic prosperity but caused pollution problems, many countries began paying more attention to the issue of air pollution and today environmental regulatory authorities around the world require manufacturing industries to keep track of pollutant emission rates by using Continuous Emission Monitoring Systems (CEMS). In the course of their daily operations, most industrial activities produce emissions of gases and particulates as a byproduct of their processes and CEMS are useful tools in gathering process emissions data for environmental compliance, process control and optimization.

While CEMS has become more and more common, its system architecture is also getting more complex and must implement new meters, analyzers, or other relevant devices due to increased standards and regulations by the supervision of the environmental protection agencies. The question arises of how do we achieve the optimal monitoring results without sacrificing performance whilst simplifying the integration process with easy maintenance?

System Requirements:

In recent years, the Chinese government has realized the urgency of addressing environmental issues and mandated the installation of CEMS at state-controlled key polluting facilities in order to provide direct, real-time, continuous measurement of sulfur dioxide (SO2), nitrogen oxide (NOX) and carbon dioxide (CO2) emissions. A CEMS developer in Zhejiang Province is designing its latest product and intends to adopt a simple but powerful model instead of its original more complicated system architecture.

Since the new CEMS will be used in severe environments such as coal-fired power stations, steel mills, cement plants, chemical plants, industrial furnaces, waste incineration, it is necessary that the devices are robust and can operate in a broad temperature range. To reduce setup time and maintenance work simple installation is another focus because those on-site devices are far away from the control room.

System Description:

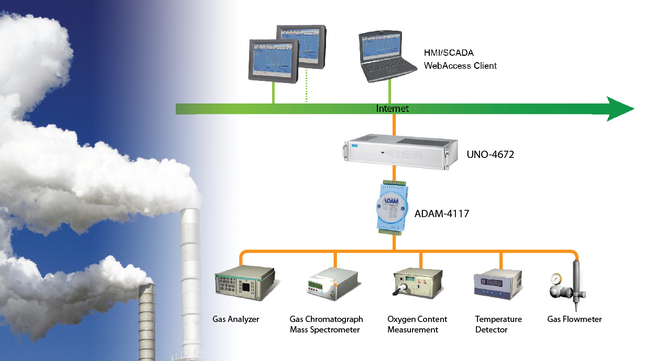

A combination of ADAM modules and UNO computers from Advantech can be a cost-effective solution to satisfy client’s demands. An ADAM-4117, an 8-ch Analog Input Module with Modbus, acquires smoke concentration and flue gas parameters as well as measuring flow, pressure, and temperature, so the on-site data can be directly sent to an UNO-4672, industrial grade automation computer with Intel Pentium M/Celeron M processor. Based on such an approach, customers can optimize their system structure with a single RS-485 cable thereby not requiring complex wiring. Both of Advantech’s products are of a robust design and support wide operating temperature ranges. In order to guarantee reliable performance in critical environments, ADAM module’s meet FCC Class A and CE, and the UNO computer is compliant with IEC-61850-3. Advantech also provided anADAM-4024, 4-ch Analog Output Module with Modbus, to connect to the client’s existing DCS system according to the application requirements of the power plant. Furthermore Advantech’s solution is expandable so it can grow as client’s applications develop.

Project Implementation:

| Product |

Description |

| ADAM-4024 |

4-ch Analog Output Module with Modbus |

| ADAM-4117 |

Robust 8-ch Analog Input Module with Modbus |

| UNO-4672 |

Intel Pentium M/Celeron M Automation Computer with 6 x LAN, 10 x COM, 8 x DI, 8 x DO, PC/104+ |

System Diagram:

Conclusions:

For CEMS, data acquisition is a major part of collecting and recording real-time data and it should be able to monitor important system parameters and easily communicate over the client’s network. Advantech provides these excellent and suitable products to provide a complete solution for quick construction and easy maintenance. Meanwhile, we also believe that modular architecture, with its many advantage, will enhance CEMS applications while monitoring all sources of harmful emissions as it increasingly becomes a global issue.