Intelligent Wireless Communication Solution for Warehouse

Project Introduction:

In order to improve the lower response and inefficient management of traditional logistics, the modern intelligent warehouse advocates adopting the latest Automated Guided Vehicle (AGV) system to greatly increase the intelligent level of logistics warehousing management as well as enhancing the system efficiency.

An AGV (Automated Guided Vehicle) is a battery powered driverless truck equipped with electromagnetic, optical or other automated guidance devices to automatically move them along the guide path. AGV’s provide safety protection and a variety of functions for the carrying and movement of goods. Typically its route and behavior are controlled by a computer system and the electromagnetic guidance system can also set up the AGV’s traveling route and can enable the vehicles to follow the path signals to move and carry.

For the purposes of reducing the complex operation and labor resources, the modern warehouse needs high-speed, convenient logistics channels while its automation application should be upgraded to the next level to ensure the quick response and shorten the transport time of materials so as to maximize the plant’s productivity. An AGV system is compatible with the needs of an intelligent warehouse since they play an important role in quick logistics and intelligent management. But how is the status of the AGV controlled when goods are being transported and loaded and how is the safe transfer of goods from warehouse to production line guaranteed and given greater priority? It is these issues and more that have become essential for logistics engineers when programming AGV’s.

System Requirements:

The monitoring system for an AGV needs to read data to understand the operational status and traveling routes of the vehicles as well as providing the fault alarm and current status of materials. Meanwhile, the timeliness and accuracy of the system is also an important requirement so that the control center can start or stop the vehicle when it is in operation to prevent accidents and cause further dangers. In order to monitor the vehicle’s running condition and predict the possibility of accidents, Advantech has introduced a communication solution for the vehicles and the control room.

AGV monitoring systems consist of three parts: configuration control software, communication system and in-vehicle PLC, and their functions are described below:

- Configuration control software: to monitor the operational condition and traveling routes of AGV as well as providing the fault alarm and current status of materials. If anything goes wrong when the vehicle is in operation, the control center can start or stop the vehicle to prevent accidents.

- Communication system: the system includes a high-speed redundant fiber optic ring network and is equipped with a number of wireless APs and wireless serial device servers to provide reliable communication between the control center and the AGV.

- In-vehicle PLC system: the system is responsible for feeding back information of a vehicle’s status and the providing the relevant instructions to control the AGV in real time.

Project Implementation:

| Product |

Description |

EKI-6311GN |

IEEE 802.11 b/g/n Wireless Access Point/Client Bridge |

EKI-1351 |

1-port RS-232/422/485 to 802.11b/g WLAN Serial Device Server |

WebAccess |

A browser-based software package for HMI and SCADA devices

|

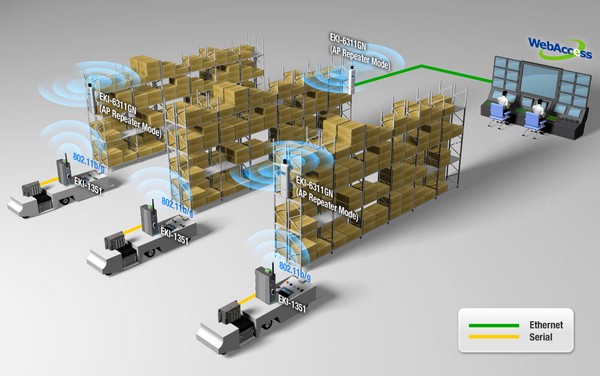

System Diagram:

System Description:

An AGV communication system is composed of three parts: the wireless AP, serial device server, and configuration software. Its backbone network uses wireless communication architecture to connect the vehicle's terminals through the wireless AP so as to ensure a stable and convenient communication.

Advantech's EKI-6311GN Wireless Access Point with a high performance controller and is an IEEE 802.11n compliant device capable of providing 3 times higher data rates than legacy 802.11g products. The EKI-6311GN also supports the STP and IGMP snooping protocols to effectively improve the reliability of wireless connectivity. In terms of network security, the EKI-6311GN offers a range of encryption methods including 64/128/152-bit WEP data encryption and WPA2/WPA/802.1x. It also supports PoE power supply mode which facilitates on-site power connection.

Through the use of an EKI-1351 WLAN serial device server, the devices with industrial bus can seamlessly connect to the network. One end of the serial port connects to the in-vehicle PLC of the AGV, and the other end uses Wi-Fi to enable network transmission. Advantech's EKI-1351 is a WLAN serial device server which supports the 802.11b/g protocol and can efficiently connect to the host via Wi-Fi. With the EKI-1351, the RS-232/422/485 serial device’s I/O data can be transferred to the host computer. Meanwhile, the data can be converted by EKI-1351 thereby freeing the company of the need to perform software programming whilst improving efficiency and reducing development costs.

Industrial configuration software has been widely used in automatic data acquisition and control systems. It plays a key role in the control of hardware interfaces from device drivers to data collection. Accessible through a web-browser Advantech WebAccess allows users to remotely-control and configure automation equipment through the browser software or even across the Internet. WebAccess’s design concept is that of a central database and distributed system architecture to integrate the automatic device acquisition, Human Machine Interfaces (HMI) and monitoring application as a complete and powerful monitoring configuration software.

Conclusion:

In this case, Advantech provides flexible and efficient WebAccess configuration software, the high-efficiency industrial wireless AP product with anti-interference ability, and the wireless serial device server to seamlessly connect between the serial port and network protocol. This solution guarantees the safe, stable and efficient operation for the AGV monitoring system of an intelligent warehouse. Furthermore, Advantech’s industrial automation products provide the hardware and software to build an integrated solution as well as satisfying the highest standards in industrial environments and our customers’ needs. |