Ship Lock Control System with WebAccess

Environment and Facility Monitoring System

Beijing, China

|

|

Project Introduction:

Lock control systems are used to raise and lower the levels of water to allow vessels access. In sections with large water level differences, they control the water line by using a ship lock to ensure the safety of passing ships. Generally operation rooms will be established at both upstream and downstream valves to realize centralized and separate operation at the same time. What’s more, the general control room and electromechanical maintenance room need to be integrated, so as to monitor real-time field conditions.

|

System Requirements:

To ensure the safe navigation of passing ships, engineers must properly control the upstream and downstream head valves and avoid mistaken operations that could lead to accidents, so the system gives strict rules on joint lock and operation authority. In the event a problem occurs, the system must immediately notify working operators and remote electromechanical serviceman to deal with it. Not only must conditions be monitored in the operation room, but also electromechanical maintenance rooms and management rooms, so the system must be empowered with powerful network functions and able to realize remote network monitoring.

Project Implementation:

|

WebAccess |

Browser-based HMI/SCADA Software |

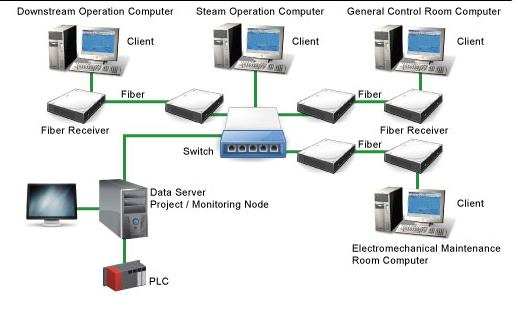

System Diagram:

System Description:

The entire system is linked through WebAccess with Ethernet network, from the PLC to the various operation centers. The PLC is used for data capturing, transmission and logic and sequential control, and to help transfer this data to multiple locations with various languages, WebAccess supports standard SQL syntax, making database inquiries, updates, insertion and deletion easy. This allows users to easily convert the database to SQLServer or Oracle, and WebAccess can automatically connect and establish the needed datasheet, saving complicated operation and database errors. It is important for the system to block unauthorized access, and limit operation authority. WebAccess can separate users into many types, and different users have different interface access authority.

WebAccess provides an alarm system to display the real-time process and device condition to operators. The alarm modes range from highest, high, low, lowest, difference, change rate and others. There is also an analog alarm that includes alarm summaries, filtration, priority, order, historical records, real-time adjusted values, voice alarms, and more.

Conclusion:

WebAccess was the best choice as the monitoring software for this facility management system. Not only can it help communicate with the various control rooms that use different languages and data sets, but also provides real-time monitoring and advanced security (such as different levels of operation authority) which is highly important when the lives of many crew members could be in jeopardy if there is an accident or unauthorized access in the lock system.

|