Production Automation

China

|

|

Project Introduction:

Jet engine testing is a complicated and tricky process. Due to the expensive cost of fuel and materials, testing needs to be implemented quickly with high sampling speeds and precision. Large-sized engines needs to be mounted on an engineering vehicle for field tests. In these scenarios the system has to be shock-proof and interference resistant in order to ensure safe and reliable test results.

|

System Requirements:

The Italian railway company was looking to upgrade their telephone infrastructure to allow integration with advanced features and functions for different environments with redundancy and remote control capabilities. This led to the following requirements:

- High sampling speed

- High sampling frequency

- Shock-proof and interference resistant

- Suitable for various engine tests

- Standard communication protocol for convenient program modifications/updates

Project Implementation:

|

PCM-3813I |

100 kS/s, 12-bit, 32-ch Isolated Analog Input PCI-104 Module

|

|

PCM-3730I |

32-ch Isolated Digital I/O PCI-104 Module

|

|

PCM-3725 |

8-ch Relay and Isolated Digital Input PC/104 Module |

|

PCM-3610 |

2-port RS-232/422/485 PC/104 Module with Isolation Protection |

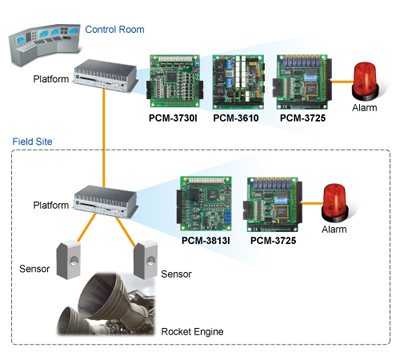

System Diagram:

System Description:

Jet engines should be tested strictly at the test facility before being put into production. Under controlled conditions, data is gathered from the sensors then transmitted to an industrial computer in the field site, and finally measured and verified in the control room.

Advantech’s analog input module, PCM-3813I, is used for monitoring data which is changing continuously, such as fuel flow, pressure and temperatures. The digital input/output module, PCM-3730I, is used for controlling actions, such as failure alarms, interlock control and emergency shutdown. It can be mounted directly on an engineering vehicle for field measurements. In between, the communication module with isolation protection, PCM-3610, is used to connect computing platforms via RS-232/422/485.

Installed at both the field site and control central site, the PCM-3725 ensures digital I/O control will work properly during test procedures while the relay function can activate an alarm in the event of a defect or error during testing. All signals sampled during the testing can be transferred to the central computer via standard PC/104 or PCI-104 interface.

Conclusion:

In order to resist the extreme vibrations and heat during jet engine testing, the systems at the test facility are required to be extremely robust. These modules need to support multi-channel/optical isolation communication with fast data sampling and high precision via standard PC/104 interface. Advantech’s rugged I/O modules proved the perfect solution with shock-proof designs and superior interference resistance. With standard driver programs and measuring software, our customers can develop programs by themselves or easily update the testing software based on different requirements. |