|

| |

|

|

Oil Field Drilling Oil Field Drilling

Pump Station Pump Station

Oil Pipeline Oil Pipeline

Tank Storage Tank Storage

Nature Gas Compressor Nature Gas Compressor

Fueling Station Fueling Station

|

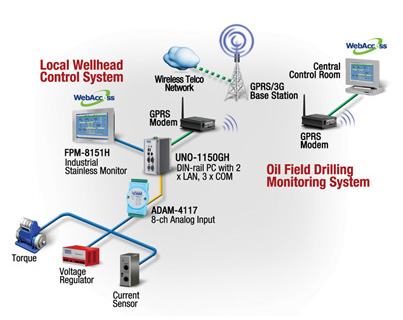

Oil Field Drilling Monitoring System

An oil field is a region with an abundance of oil wells extracting petroleum from

below ground. Because the oil reservoirs typically extend over a large area,

possibly several hundred kilometers across, full exploitation entails multiple wells

scattered across the area. In addition, there may be exploratory wells probing the

edges, pipelines to transport the oil elsewhere, and support facilities. Because an

oil field may be far away from civilization, establishing a field is often an extremely

complicated logistical exercise. |

|

System Description

This system was created to help monitor the status of drills in an oil field, automatically alerting technicians if the torque, voltage, current or amp values exceed safe limits. These sensors are connected to an

ADAM-4117, which is connected to a UNO-1150GH for data processing and an FPM-8151H for local display and monitoring. This system is built at the base of the oil drill and connects back to the central control room though a GPRS modem. This allows the control room to monitor over 800 drills across multiple oilfields with the help of WebAccess.

Benefits

Advantech WebAccess is browser-based HMI/SCADA software package designed for powerful architectures with multiple SCADA servers and client applications. All the features found in conventional HMI and SCADA software packages, including Animated Graphics Displays, Real-time Data Control, Trends, Alarms and Logs for efficient remote diagnostics and maintenance are available through a standard web browser.

|

|

Pump Station Monitoring System

The oil & gas industry includes the global processes of exploration, extraction,

refining, transporting, and marketing petroleum products, such as oil, which is

transported through large pipes that can stretch across continents. The oil is

kept in motion by pump stations along the pipeline, and usually flows at a speeds of

about 1 to 6 meters per second. |

|

System Description

This application was for a monitoring system placed in pump stations along a cross-continental pipeline. Every 30km is a pump station to help keep the oil flow in motion, with over 80 pump stations in total. This system allows the engineers to monitor all of the stations from a central control room through WebAccess. In the pump station itself there are many different sensors installed, including metering, pressure, and temperature gauges. These sensors are linked to a PLC which is connected to an UNO-1150GH for data processing, and an FPM-8151H which allows local technicians to check the status of the pumping process as well. These devices are then connected to an EKI-7559SI, which transmits data back to the central control room through fiber optic cabling.

Benefits

Class I, Division 2 certification guarantees reliable performance in the harshest environments, while EKI-7559SI's fiber optic capabilities allows the engineers in the central control room to accurately and precisely view the status of each pump station, giving them time to respond in the event action needs to be taken.

|

|

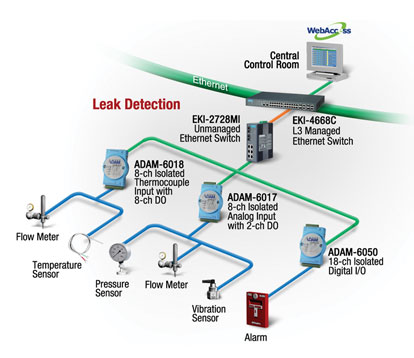

Oil Pipeline Monitoring

Oil pipelines are made from steel or plastic tubes with inner diameter typically

from 4 to 48 inches. Most pipelines are buried at a typical depth of about 3 to

6 feet. As crude oil contains varying amounts of wax, buildup may occur within

a pipeline. Often these pipelines are inspected and cleaned using pipeline

inspection gauges, used to detect anomalies in the pipe such as dents, metal

loss caused by corrosion, cracking or other mechanical damage. |

|

System Description

This system helps monitor the temperature, pressure, flow and vibrations in an oil pipeline that stretches hundreds of miles from China into Russia, and transmits this data back to a central control room. All of the sensors are connected to a series of ADAM modules: ADAM-6017, ADAM-6018 and ADAM-6050. These modules help process the data, and through an EKI- 2728MI, transmit it to the central control room.

Benefits

ADAM-6018 is the most prevalent temperature data acquisition module in today's industrial automation market. In addition to 8 T/C input channels, the ADAM-6018 is also equipped with 8 digital output channels such as auxiliary alarm outputs or pure outputs. ADAM-6017 is designed with 8 analog inputs and 2 digital outputs to satisfy all plant needs. Each analog channel is allowed to configure an individual range for variety of applications. ADAM-6050 is a high-density I/O module built-in a 10/100 based-T interface for seamless Ethernet connectivity. It provides 12 digital input and 6 digital output channels with 2000VRMS Isolating protection.

|

|

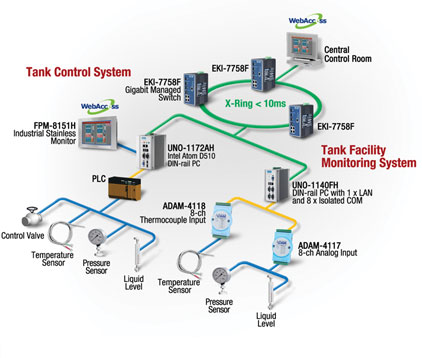

Tank Storage Monitoring

This application was setup to help monitor a fueling operation. The

information & machine diagnostic data will be collected and sent back to

the office and corporate headquarters. An accurate monitoring system not

only measures fuel levels, but also temperature and estimated volume

information. |

|

System Description

There are over 400 Liquefied Natural Gas storage facilities connected in this system that aims to provide two major functions: local tank control, and remote monitoring. Most oil, fuel, or chemical tank storage units locate at hazardous areas that require constant monitoring of pressure, liquid levels, control valve position, and temperature. A SCADA-based system for real-time data collection and transmission is essential for plant and personnel safety. A PLC is installed to handle local tank control. All control & monitoring data are processed by an UNO-1172AH Intel Atom D510, 1.6 GHz computer and can be accessed by the central control room through EKI-7758F Ethernet switches.

Benefits

In the remote monitoring system of local tanks, the temperature, pressure and liquid levels need to be sent to central control room.UNO-1140FH provides 8 serial communication ports and fast Ethernet interfaces. ADAM-4117 AI and ADAM-4118 thermocouple modules control pressure, liquid level and temperature data acquisition. The technicians in the central control room use Advantech WebAccess, web-based SCADA software, to view and analyze data from all of the fuel stations. WebAccess, web-based SCADA software, to view and analyze data from all of the fuel stations.

|

|

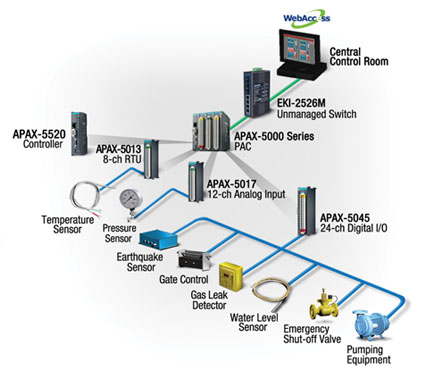

Natural Gas Compressor Monitoring System

In many cities worldwide there are stations responsible for compressing gas into low

pressure for transferring to businesses and households. The interval between compressor

stations is usually every 50 to 100 miles along a pipeline. Proper monitoring is critical to

ensure safety, as natural gas can be dangerous and explosive if not controlled. |

|

System Description

Many compressor stations are unmanned, and require reliable monitoring systems. Powerful PAC is an ideal platform for performing data acquisition, logging and local emergency control tasks. Running programs on an APAX-5520 controller, the Advantech's APAX systems can obtain pipeline pressure and temperature data from sensors through APAX-5013 and APAX-5017 analog input modules, and send this data back to a central control room. Local storage capacity allows the system to know when the network between local PAC and remote control center is down, or if any unexpected accident occurs, the system can control the valve to automatically suspend gas transportation.

Benefits

Advantech's APAX PAC solutions deliver reliable and continuous

monitoring capabilities; allowing compressor stations to operate safely even with no technicians on hand, providing a safe and secure

environment for gas compression and transportation.

|

|

Fueling Station Management

This project implemented a gasoline pump control system for the dispensing,

metering, and monitoring of gasoline tanks at a gas station. This fully automated

system manages the process of dispensing gasoline and is supported by real-time

connectivity between the gas station and its corporate headquarters. |

|

System Description

The control & management platform is a UNO-1140FH integrated with the ADAM-4000 series as a turn-key solution. An ADAM-4080 counter/frequency Input module with two 32-bit counter input channels and a built-in programmable timer for frequency measurement helps to manage the details of the fuel dispenser meters data and ADAM-4117 analog input modules gather tank liquid levels, and pressure information. The ADAM-4150 digital input/output module is in charge of alarms triggers and switching pumps on/off. Then the control & management platform can transmit all information via EKI-2728MI Ethernet switch to the corporate headquarters.

Benefits

In this application Advantech's complete turn-key system & software provided a good cost-effective solution. All the products installed provide excellent safety & reliability. The ADAM-4100 series modules are compact, versatile sensor-to-computer interface units are designed for reliable operation in harsh environments. Their built-in microprocessors, encased in rugged industrial-grade ABS plastic, independently provide intelligent signal conditioning, analog I/O, digital I/O, LED data display, and an address mode with a user-friendly design for convenient address reading.

|

|

|

|

|

Oil Field Drilling

Oil Field Drilling

Pump Station

Pump Station

Oil Pipeline

Oil Pipeline

Tank Storage

Tank Storage

Nature Gas Compressor

Nature Gas Compressor

Fueling Station

Fueling Station